No products in the cart.

Blog

Unlocking Brilliance: A Guide To Polyester T shirts For Sublimation Printing

In the dynamic world of custom apparel, sublimation printing has emerged as a revolutionary technique, breathing life into designs with unparalleled vibrancy and durability. Among the various canvases for sublimation, polyester t shirts for sublimation stand out as the preferred choice, offering a perfect marriage of fabric composition and print quality. Whether you’re a seasoned sublimation expert or a novice exploring the possibilities, this guide is designed to equip you with the knowledge needed to create stunning, long-lasting prints on polyester canvas. Let’s dive in!

Key Characteristics Of Polyester T Shirts For Sublimation

Fabric Composition

Optimal Polyester Content For Sublimation

The Power of Polyester:

Polyester’s synthetic nature makes it an ideal canvas for sublimation printing. Unlike natural fibers, such as cotton, polyester allows the sublimation ink to fully penetrate the fabric, resulting in vivid and long-lasting prints.

Finding the Sweet Spot:

While a 100% polyester fabric is often recommended for sublimation, blends can also be effective. A polyester content ranging from 95% to 100% is considered optimal for achieving sharp, high-quality prints.

Blends and Considerations:

Some T-shirts come with polyester blends, combining it with other fabrics like cotton or spandex. While blends can offer unique textures and comfort, it’s essential to ensure that the polyester content is high enough to facilitate effective sublimation transfer.

Enhancing Color Saturation:

Higher polyester content enhances color saturation, ensuring that your prints appear vibrant and true to the intended design. This is particularly crucial for intricate or detailed artwork where color accuracy is paramount.

Durability and Longevity:

Polyester’s inherent durability makes it resistant to fading, ensuring that sublimated prints maintain their brilliance even after numerous washes. This longevity is a key advantage, especially for those seeking a lasting impact with their custom designs.

Considerations for Specialty Fabrics:

Keep in mind that some specialty polyester fabrics, such as moisture-wicking or performance blends, can also be sublimated successfully. Understanding the unique characteristics of these fabrics will allow you to adapt your sublimation process accordingly.

Blend Considerations For Enhanced Sublimation Results

Polyester-Cotton Blends:

T-shirts made from polyester-cotton blends offer a combination of the softness of cotton and the sublimation-friendly characteristics of polyester. While these blends can be sublimated successfully, it’s essential to note that the presence of cotton may affect color vibrancy. Designs may appear slightly muted compared to those on 100% polyester fabric.

Polyester-Spandex Blends:

Blending polyester with spandex introduces stretch and flexibility to the fabric. This blend is popular in activewear and sportswear. When sublimating on polyester-spandex blends, consider the elasticity of the fabric to ensure that the print stretches without distortion.

Tri-Blend Fabrics:

Some T-shirts feature a tri-blend composition, typically combining polyester, cotton, and rayon. While these blends offer a comfortable and vintage feel, they may not be as conducive to sublimation as higher-polyester content fabrics. Designs on tri-blend T-shirts may appear faded or less vibrant.

Moisture-Wicking Blends:

T-shirts designed for athletic or outdoor activities often feature moisture-wicking blends, which are engineered to keep the wearer dry. When sublimating on moisture-wicking fabrics, consider the impact of the fabric’s technology on the sublimation process. Adjusting temperature and pressure settings may be necessary to accommodate these specialty blends.

Blended Textures:

Some blends may have unique textures, such as heathered or mélange effects. While these textures can add visual interest to your designs, it’s crucial to test how they interact with the sublimation process. Uneven textures may result in variations in print clarity.

Blends with Natural Fibers:

Blends that include natural fibers like bamboo or hemp may introduce eco-friendly elements to your T-shirts. However, these natural fibers may not sublimate as effectively as polyester. It’s advisable to test these blends to ensure satisfactory results.

Weight And Thickness

Impact Of T-Shirt Weight On Sublimation Quality

The weight of a t-shirt plays a significant role in determining the quality of sublimation prints. Sublimation is a printing technique where heat and pressure are applied to transfer ink onto a material, creating vibrant and durable prints.

In the case of t-shirts, the weight of the fabric affects the absorption and retention of the sublimation ink. Lighter-weight t-shirts tend to absorb the ink more readily, resulting in brighter and more vivid colors.

However, this increased absorption can also lead to a softer feel of the print and may reduce the overall longevity of the design, as the ink is more prone to fading or washing out over time. On the other hand, heavier-weight t-shirts provide a more substantial base for sublimation, allowing for better ink retention and potentially enhancing the durability of the print.

The challenge lies in striking a balance between fabric weight and the desired characteristics of the sublimation print, taking into consideration factors such as comfort, longevity, and vibrancy.

Choosing The Right Thickness For Durability And Print Vibrancy

Selecting the appropriate thickness for a substrate is a critical factor in achieving a balance between durability and print vibrancy in various printing processes, including sublimation. The thickness of the material directly influences how well it can withstand wear and tear over time, as well as the vividness and longevity of the printed design. In the context of sublimation printing, where color absorption and retention are crucial, finding the right thickness becomes a nuanced decision.

When aiming for durability, a thicker substrate often provides a more robust canvas for the ink to adhere to, contributing to better resistance against fading, cracking, or peeling. Thicker materials are generally more resistant to abrasion and can withstand repeated washes, making them suitable for applications where longevity is paramount. However, the challenge lies in maintaining a balance, as excessively thick materials may compromise the flexibility and comfort of the finished product.

Weave And Texture

Discussion On Smooth And Even-Textured Fabrics

The weave and texture of fabrics play a crucial role in the outcome of various printing processes, influencing the appearance, feel, and overall quality of the printed design. Fabrics that exhibit a smooth and even texture are particularly sought after in the printing industry for several reasons.

When it comes to techniques like sublimation or direct-to-garment printing, a smooth surface allows for better ink absorption and distribution, resulting in more vibrant and precisely detailed prints.

Smooth fabrics with an even texture provide a consistent and uniform surface for the printing medium, ensuring that colors are applied evenly without distortion or irregularities. This is especially important for intricate designs and patterns, as any inconsistencies in the fabric’s texture may lead to variations in print quality. Moreover, a smooth surface contributes to sharper image reproduction, allowing for fine details to be captured accurately.

Choosing The Right Polyester T-Shirts For Sublimation

Brand And Quality

Trusted Brands In The Sublimation Industry

When selecting polyester T-shirts for sublimation printing, choosing trusted brands is essential to ensure high-quality results, durability, and customer satisfaction. Several reputable brands in the sublimation industry are known for producing polyester garments that are specifically designed to optimize the sublimation process. Here are a few trusted brands that are recognized for their commitment to quality in the sublimation apparel market:

A4 Apparel: A4 is well-regarded for its range of performance-oriented polyester garments suitable for sublimation. They offer a variety of styles, including T-shirts, which are known for their moisture-wicking properties and vibrant print results.

Vapor Apparel: Vapor Apparel is a leading brand specializing in performance fabrics for sublimation. They offer a diverse range of polyester T-shirts designed for optimal color reproduction, fade resistance, and comfort. Their garments are often used for sports and outdoor activities.

JERZEES Dri-Power: JERZEES is a popular brand that offers polyester T-shirts suitable for sublimation printing. The Dri-Power line is known for its moisture-wicking capabilities, making it a practical choice for sublimated activewear.

Hanes Cool DRI: Hanes, a well-known name in the apparel industry, offers Cool DRI polyester T-shirts designed for sublimation. These shirts are valued for their moisture-wicking properties and are often chosen for sublimation projects that require both comfort and vibrant prints.

Champion Vapor: Champion is recognized for its durable and performance-oriented apparel, and the Vapor line is particularly suitable for sublimation printing. The Vapor polyester T-shirts are known for their quick-drying and breathable characteristics.

Importance Of Quality Assurance In The Manufacturing Process

Customer Satisfaction: Ensuring that products meet or exceed quality standards is crucial for customer satisfaction. High-quality products contribute to positive customer experiences, leading to brand loyalty and repeat business. Satisfied customers are more likely to recommend a brand to others, thereby fostering long-term relationships and building a positive reputation in the market.

Compliance with Regulations: In many industries, adherence to specific quality standards and regulatory requirements is mandatory. Quality assurance practices help manufacturers comply with local and international regulations, ensuring that products are safe, reliable, and meet the necessary standards for public health and safety.

Cost Reduction: Implementing effective quality assurance measures can result in cost savings in the long run. By identifying and rectifying defects or issues early in the manufacturing process, companies can avoid costly rework, scrap, or product recalls. This leads to increased operational efficiency and reduces overall production costs.

Market Competitiveness: High-quality products give companies a competitive edge in the market. Consumers are more likely to choose products that are known for their reliability and durability. Quality assurance helps companies differentiate themselves from competitors, attracting customers who prioritize the value and performance of the products they purchase.

Brand Reputation: A strong brand reputation is built on the consistent delivery of high-quality products. Negative experiences related to product quality can quickly tarnish a brand’s image and erode consumer trust. Quality assurance measures protect and enhance a brand’s reputation by ensuring that products consistently meet or exceed customer expectations.

Risk Management: Quality assurance is a crucial component of risk management. By identifying potential issues early in the manufacturing process, companies can proactively address and mitigate risks. This includes preventing defects, minimizing the likelihood of product failures, and reducing the impact of unforeseen challenges.

Pros And Cons Of Pre-Treated Polyester T-Shirts

Pros of Pre-Treated Polyester T-Shirts:

- Convenience: Ready for sublimation, saving time and effort.

- Consistent Results: Controlled treatment for uniform prints.

- Ideal for Small-Scale Production: Efficient for individual or small projects.

- Reduced Risk of Mistakes: Professional pre-treatment minimizes errors.

Cons of Pre-Treated Polyester T-Shirts:

- Limited Flexibility: Less control over the sublimation process.

- Cost Considerations: Higher price compared to untreated options.

- Dependency on Supplier Quality: Quality relies on the supplier’s pre-treatment.

- Limited Options for Customization: Constraints in customization.

- Environmental Concerns: Chemicals used in pre-treatment may pose environmental issues.

Considerations For Those Who Prefer To Treat Their Own Shirts

Fabric Selection:

Choosing the right type of polyester fabric is crucial. Opt for fabrics with a high polyester content (ideally 95% to 100%) to ensure optimal sublimation results. Consider factors like weight, weave, and texture based on your design preferences and the intended use of the T-shirt.

Pre-Treatment Solution:

Selecting an appropriate pre-treatment solution is a critical step. Different solutions are available in the market, each with its own set of instructions. Follow the manufacturer’s guidelines to ensure proper application and effectiveness. Consider eco-friendly options if environmental concerns are a priority.

Application Process:

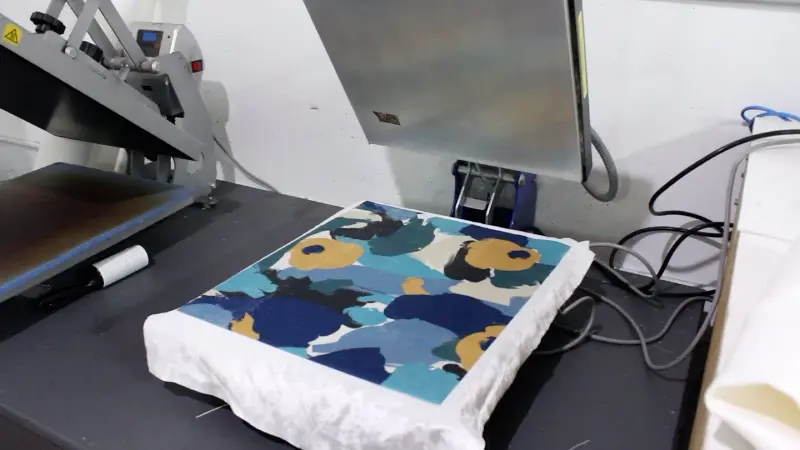

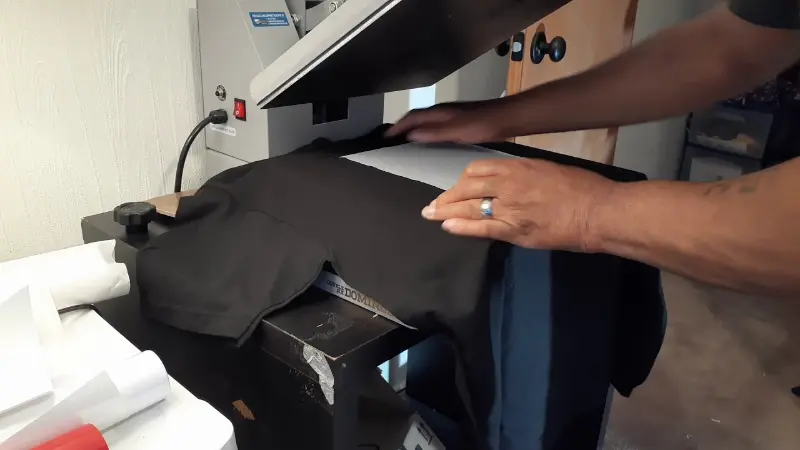

The application of the pre-treatment solution requires precision. Use a consistent and even application to avoid uneven printing results. Pay attention to drying times and curing methods specified by the manufacturer to ensure the treated fabric is ready for sublimation.

Equipment and Workspace:

Create a dedicated workspace for pre-treatment, equipped with the necessary tools. Ensure proper ventilation and use protective gear if handling chemical solutions. Invest in quality equipment, such as a spray gun or roller, to achieve uniform pre-treatment coverage.

Testing and Calibration:

Conduct test prints on treated fabric scraps before working on the actual T-shirts. This allows you to fine-tune the pre-treatment process and calibrate your sublimation equipment for optimal results. Testing helps identify and address any issues before committing to the final prints.

Conclusion

In the realm of custom garment decoration, the choice of polyester T-shirts for sublimation printing proves to be a gateway to a world of vibrant creativity and lasting impressions. Through the exploration of optimal polyester content, blend considerations, the impact of T-shirt weight, and various other factors, we’ve uncovered the keys to unlocking the full potential of sublimation on fabric.